Composite Construction for Scotland

What is composite construction?

You may have heard of ‘composite steel deck’ or ‘composite metal deck’? Well these often-used terms are, in fact, slightly misleading.

It’s the combination of profiled steel decking sheets acting together with a concrete slab and connected by shear studs to a steel frame that forms a composite steel deck flooring system.

It’s so effective because the steel elements resist tensile forces, the concrete resists compressive forces and together they lend strength and stiffness to a structure. The result is a lightweight, cost-effective concrete slab.

But that’s is not the only benefit of composite construction. Composite floors can be used in any steel framed structure, although typically they’re specified for multi-storey buildings such as office blocks, hotels, hospitals, schools and car parks. It’s a particularly efficient solution for inner-city development and refurbishment projects with limited site access and space.

The terms ‘steel decking’ and ‘metal decking’ cover all forms of the profiled steel sheeting commonly used in these floor systems. They also come up in references to built-up roof systems, where the deck sheets act as the structural element.

What are the benefits of composite construction?

It has distinct advantages over non-composite, in-situ reinforced concrete slabs, providing a highly effective structural solution for multi-storey steel framed buildings.

- Traditional construction methods with formwork and props are avoided.

- A lighter slab means that reinforcement and other construction material requirements in the steel frame and foundations are reduced.

- Rapid installation minimises construction times while maintaining consistent quality.

- Immediately after deck installation, following trades get a safe working platform and cover.

- Composite slabs can achieve up to a 4 hour fire rating and have superior acoustic performance.

- Structurally, steel decking provides lateral restraint to the frame and tensile reinforcement for the slab.

And steel decking doesn’t necessarily have to be used as part of a composite floor system. On its own it can act as permanent formwork for non-composite, fully reinforced concrete slabs, again avoiding the use of traditional propping systems.

composite construction

TR80+ steel floor deck installation

Which steel deck product should I use?

Choosing the most suitable floor deck or roof deck profile for your project can be complex and challenging.

Your span limits, slab depth and slab loading must be considered, as well as project cost, programme and the aesthetic appearance of the soffit.

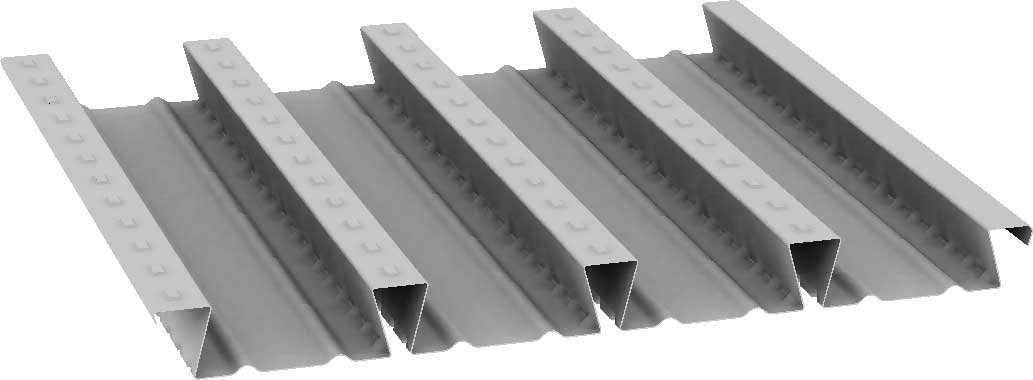

Floor decking typically comes in two profiles. The ‘dovetail’ shape has small re-entrant type ribs separated by relatively wide flat areas and the trapezoidal profiles have the distinct rib and trough shape that’s led to the use of terms like ‘corrugated steel’ and even ‘crinkly tin’.. Additional indentations and embossments serve to create a mechanical interlock and shear bond with the concrete.

We’re closely aligned with Structural Metal Decks (SMD) Ltd and we provide their market-leading products for our customers. Our four floor deck profiles are manufactured using galvanised steel strip complying with BS EN 10146 & 10346, cold-rolled into the desired profile and then cut into the required sheet lengths. The steel strip gauges vary between 0.7mm and 1.5mm and selection of the correct gauge depends on the structural and fire resistance requirements of the completed slab.

‘Which metal decking product should I use?’ provides more detail to enable you to make your choice.

Designing a composite floor system

The first question is usually “How far can metal deck span?

Our SMD decking products have varying span capacities that are in turn dependent on several factors. The span capability of the deck profile, the steel frame layout, the desired slab thickness and its required fire rating all need to be considered in the design of steel deck floor systems, as well as budget, construction programme and site access constraints.

In addition to this, temporary construction loads, wet concrete, in-service dead and imposed loads and allowable deflection of the slab must be taken into account.

Detailed design checks for our range of SMD decking profiles can be carried out by our in-house design team but you can also run a check on the bespoke Elements® Design Software.

Video tutorials are available to help you make the most of this software to design both floor and roof deck and you can also download the Elements® Span Check app to your phone as a quick and simple span look-up option. The app is available for both Android and Apple devices.

floor-and-deck-options2-1

Our composite floor systems

Reinforcement of a composite slab

Transverse reinforcement is an essential part of the slab design. The deck profile resists the tensile forces in the bottom of the slab, but the composite floor cannot perform as designed without the inclusion of some form of reinforcement in the concrete.

There are several reasons why reinforcement is required in a composite slab.

- It controls and minimises cracking of the concrete.

- It aids the distribution of load, particularly where high concentrated loads will be applied to the slab.

- It contributes to the fire resistance of the completed composite floor.

Alternatively, the concrete itself can be reinforced with steel fibres. Together with ArcelorMittal Wire Solutions, we’ve developed the TAB-Deck® steel fibre reinforced composite slab solution.

Deformed steel fibres form a mechanical bond with the concrete matrix and transform it from a brittle material into one that’s more ductile with an enhanced post-cracking behaviour and multidirectional strength.

Use of steel fibre reinforced concrete has clear benefits.

- Requirements for storage and manual handling of steel mesh are avoided and concreting operations are more efficient.

- Low carbon construction is more easily achieved as the overall quantity of steel as a raw material is reduced.

Our design guidance document ‘Steel Fibre Reinforced Concrete Slabs on Metal Decking’ explores this concept in more detail.

What do shear studs do?

Composite beams are those which act together with the slab and deck via shear connectors, usually in the form of thru-deck welded studs.

Apart from anchoring the deck, studs enhance the load carrying capacity and stiffness of the beams. They also transfer horizontal shear forces between the steel beam and the concrete slab.

When designing a composite beam, the structural engineer calculates the number of shear studs required and must also specify that the top flange is left unpainted and contaminant-free to avoid a poor connection.

Our article “What is a shear stud for?” goes into detail on such topics as shear stud configuration rules (are they single, in pairs or staggered?), minimum and maximum spacings of studs and practical considerations that must be made when installing studs.

Composite floors for multi-storey car parks

Steel deck construction is often the preferred choice for car park projects due to its cost effectiveness, durability and structural benefits. Multi-storey car park slabs are vulnerable to wet weather conditions, airborne and de-icing salt and can also suffer damage from tight circulatory vehicle movements.

SMD’s technical guidance on car park slab design considerations goes into further detail on the types of profiles to be used, various slab options and the practical considerations.

Composite construction is an ideal choice for multi-storey car parks as it allows for large spans and in these potentially aggressive environments, the deck profiles can be given a protective coating.

Steel decking in aggressive environments

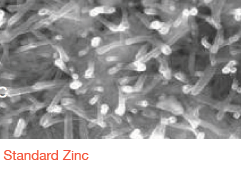

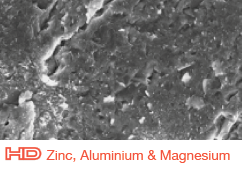

SMD decking can be specified with a HD high durability coating that enhances longevity and provides corrosion resistance in aggressive environments, ideally suited for use in car parks, buildings in seaside locations and structures housing swimming pools.

The HD coating provides excellent corrosion resistance when compared to the standard hot dip galvanised coating.

Similarly, the TR80+ profile can be supplied with a PF Plastisol coating that improves its durability as well as forming a more attractive surface where left exposed.

As thru-deck welded shear studs cannot be used with coated sheets or on painted beam flanges, both of which may be requirements in a corrosive environment, the use of pre-studded beams, or shop-welded studs, may be the only option here. In these cases, it’s an advantage to use the TR80+ profile in single-spanning sheets, supplied with what we call ‘crushed ends’.

What are the advantages of ‘crushed ends’?

The term is an apt description in itself, although it’s also known as ‘engineered ends’. The trapezoidal deck profile is rolled as normal, but after the sheets have been cut to size, the ends of the ribs are compressed, or crushed. The result is that the ribs slope down to the beam flange, providing a greater volume of concrete over each beam, with enhanced shear stud performance, reducing the need for end caps to prevent grout loss and making installation on pre-studded flanges faster.

As with all product options, however, crushed ends aren’t suitable for all projects and all steel arrangements so please consult with our technical team if you’re not sure.

Steel decking in roof construction

Certain trapezoidal steel decking profiles are used to support built-up roof systems, green roofs and standing seam systems with the deck spanning between steel beams or purlins and acting as a structural platform for the other materials.

The use of metal decking in roof construction provides cost effective installation and efficient noise and heat insulation. The decking is durable and aesthetically appealing for exposed soffits and, due to its long span capacity, fewer intermediate supports are required.

Like floor deck, structural steel roof deck can also act as a diaphragm to transfer wind loads from the perimeter elevations to internal vertical bracing or walls.

Our design tools and guidance

Our brochure provides detailed information on our products and services as well as on our many technical resources to help you with your design.

In addition, SMD’s comprehensive technical guidance notes, TGN Online, is informative and easy to use.

To assist engineers and designers to adopt BIM Level 2, our products are available as BIM components, directly from SMD or on BIM Store. These can be used in software such as Autodesk Revit. All BIM components come with the manufacturer’s details and CoBie data attached. They’ve been created by BIM Store’s development department, so you can be sure that the content is in line with industry best practice.

Can you get a complete steel decking package in Scotland?

Short answer – yes. Our customers don’t need to juggle several small work packages with separate suppliers and all the associated logistics in order to achieve complete floor construction.

Our service starts with design and supply of deck profiles and continues on site with the installation of deck and shear studs and finally concreting. We also set up our own safety netting and you can add service void protection into the package.

We are Scotland’s local steel decking specialists.