The Steel Construction Institute (SCI) have revised its P300 publication, “Composite Slabs and Beams using Steel Decking: Best Practice for Design and Construction,” inclusive of an update aligning roles and responsibilities with the latest iteration of CDM regulations. In the list below some of the key design aspects within a composite beam/slab are covered with an indication of where the design responsibility typically sits and of how Thrudeck can help at each stage of the design.

Shear Stud Type and Quantity: Determining the type and quantity of shear studs, crucial for steel-concrete composite beam design, falls under the purview of the project’s steel frame designer. Thrudeck offers guidance on alternative stud types, configurations, and layouts.

Product Specification: Responsibility for deck profile, grade, and thickness primarily rests with the steel frame designer. Thrudeck’s technical team leverages over 35 years of experience to recommend optimal deck profiles based on various building types and configurations.

Deck Detailing: The detailing of deck sheets, closures, and layouts typically lies with the decking contractor, often the deck supplier like Thrudeck. We conduct design reviews to identify critical issues early, ensuring seamless integration with the frame contractor’s requirements.

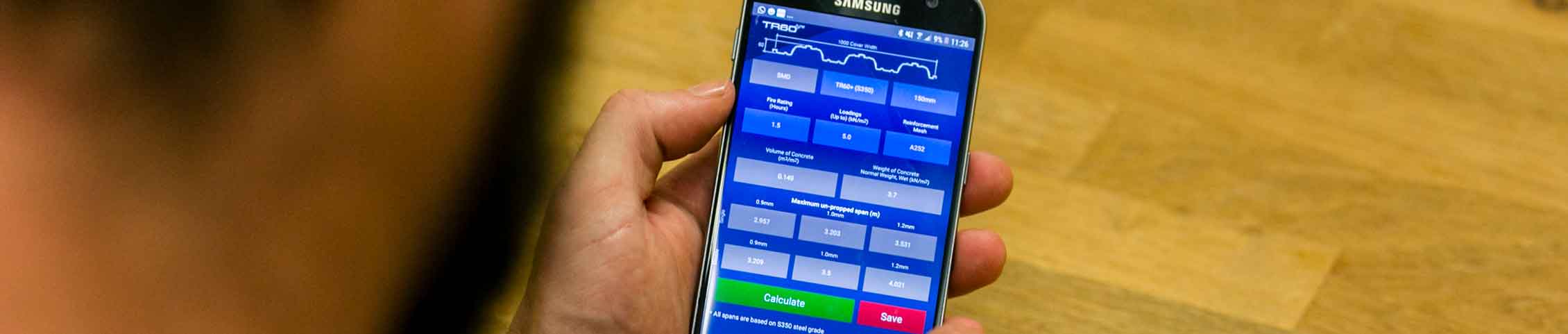

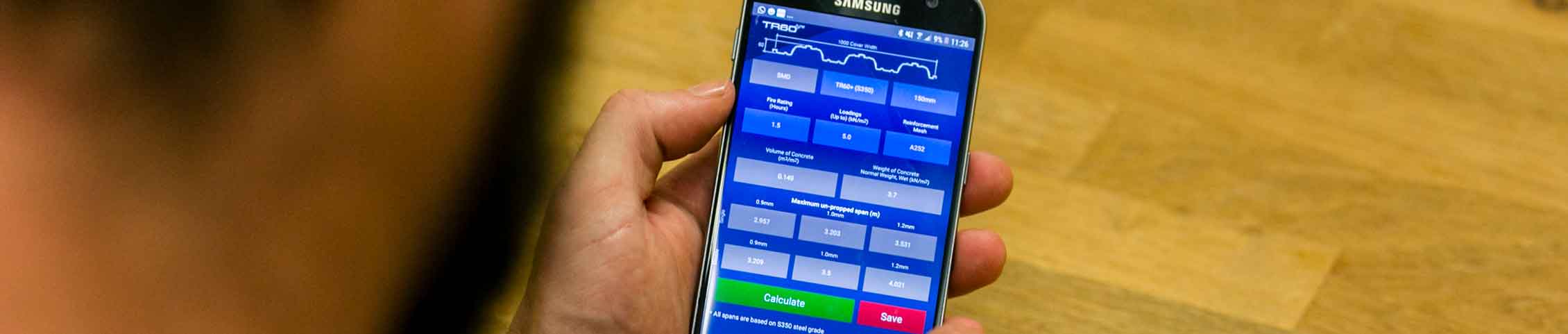

Slab Design (Reinforcement Design and Detailing): While the project’s structural engineer holds responsibility for slab design, deck suppliers like Thrudeck provide tools and support for load span tables and design software. Thrudeck offers support but emphasizes that aspects like excessive loads on cantilevers or special finishes necessitating enhanced crack control remain within the engineer’s domain.

Moreover, reinforcement required for both slab and composite beam designs, like U-bars or transverse bars, must align with the structural engineer’s oversight to prevent missed details or potential design risks.

Thrudeck offers varying levels of support for slab design, from calculations to full reinforcement detailing, albeit with additional costs and early order placement requirements.

Communication throughout a contract is key, especially if specific contractual clauses deviate from typical design roles. It’s crucial to align all parties involved, ensuring clarity on responsibilities to allocate time, resources, and finances appropriately.

We encourage early engagement with the Thrudeck team, offering guidance and experience during tender or pre-construction stages. Our aim is to assist customers and designers, providing advice, references, and valuable insights to streamline the design process within the Scottish construction landscape.